What We Do

- Home

- What We Do

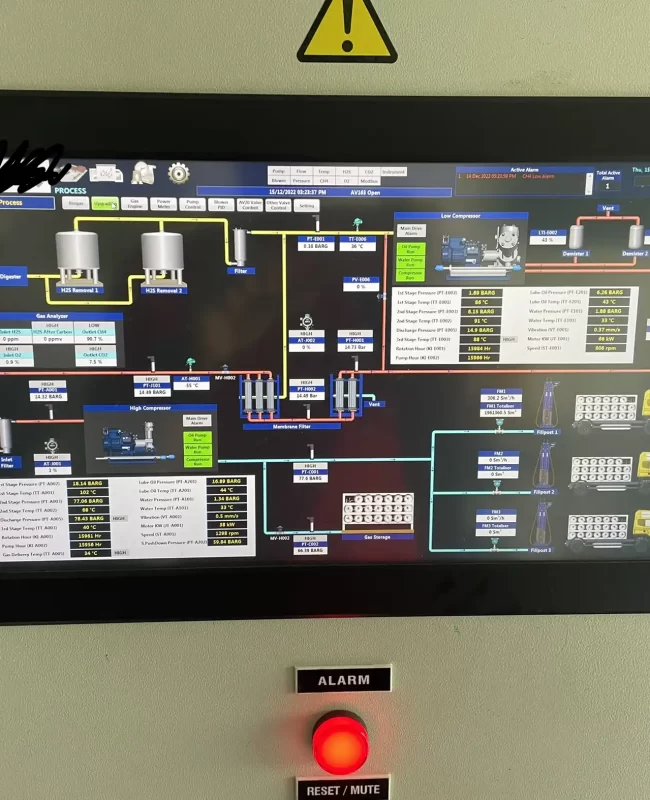

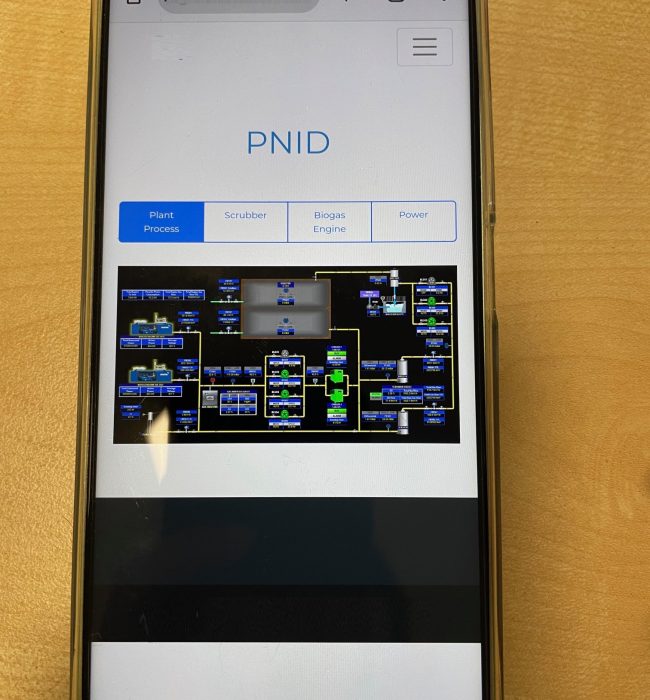

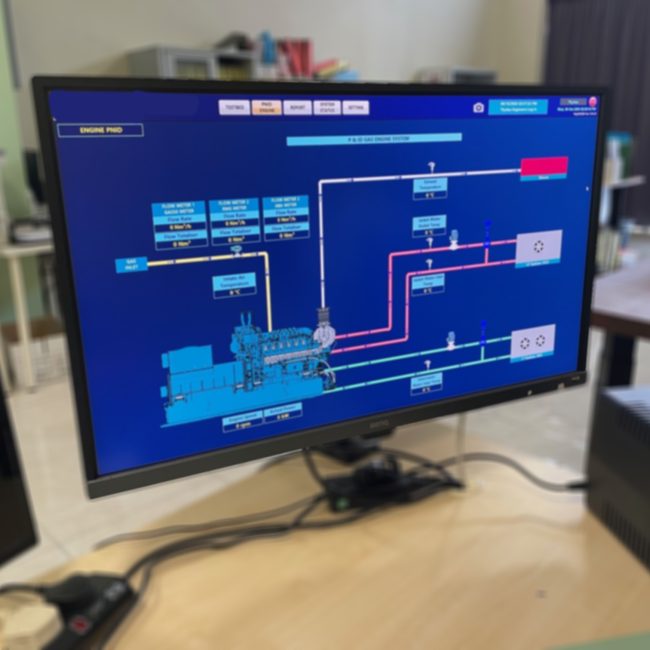

SCADA System Design and Programming

SCADA (Supervisory Control and Data Acquisition) systems are essential for overseeing, monitoring, and controlling industrial processes in real-time. They provide operators with comprehensive data and control functionalities, enabling better decision-making and operational efficiency across various industries.

Our SCADA solutions are designed with high scalability, allowing seamless expansion as your operations grow. We create customized reporting systems tailored to the specific needs of each user, delivering actionable insights and data in an accessible format.

With remote monitoring capabilities, users can access the system through both web and mobile platforms, ensuring real-time oversight from anywhere. Our dashboard features offer multiple data presentation methods, providing flexibility in how critical data is viewed and interpreted.

Key features of our SCADA systems include:

Real-time data monitoring

Offering operators up-to-the-second insights for more informed decision-making.

Seamless integration

ODBC/SQL compliant database

enabling seamless data storage and retrieval, making historical data easily accessible for reporting, analysis, and decision-making.

Robust client/server architecture

ensuring reliable communication and data flow between components, designed for both small and large-scale applications.

Redundancy system availability

Our SCADA solutions are built to optimize plant performance, streamline operations, and ensure long-term reliability, offering an all-in-one platform for effective control, monitoring, and scalability.

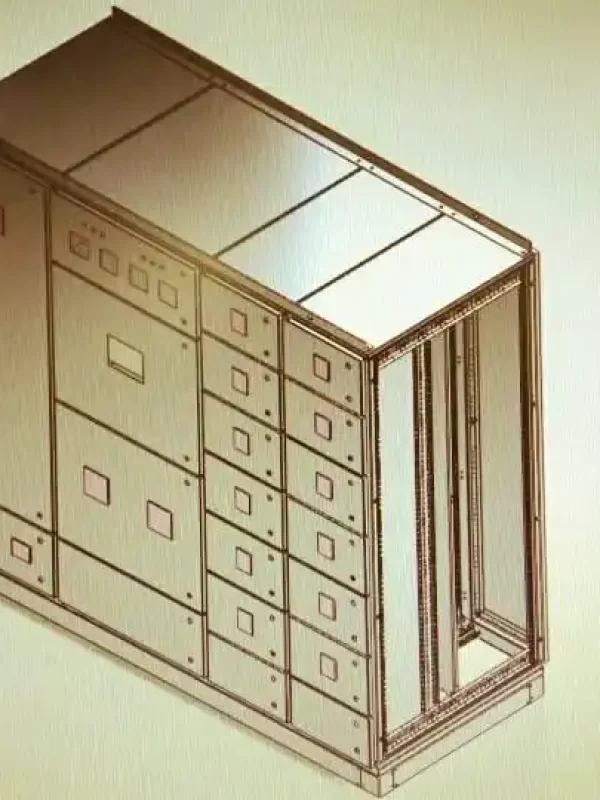

Control Panel Design and Assembly

We specialize in control panel fabrication and assembly with a focus on safety,quality and reliability. We ensure the right material combination use for different applications, providing robust solutions for various industries. Our design process emphasizes proper component selection and placement inside the enclosure, ensuring a safe and tidy layout that is easy to operate, maintain and troubleshoot, with all components clearly labeled for convenience.

Before delivery, every panel undergoes detailed inspections and testing to ensure the smooth installation and commissioning at site. We use only high-quality wiring accessories, proven to provide long service life, ensuring your control panels are built to last.

Thydaa Engineers Sdn Bhd is registered with Suruhanjaya Tenaga Malaysia under Pengilang Papan Suis for control panel assembly and manufacturing.

We ensure the right material combination use for different applications, providing robust solutions for various industries, designed to maximize savings and minimize downtime.

Great Work Lasts Longer

PLC System Design and Programming

We specialize in designing and programming PLC systems tailored to your specific needs. Our team is proficient in working with a wide range of PLC brands, including Schneider, Siemens, Mitsubishi, Allen Bradley, Omron, and more, ensuring seamless integration across various platforms.

Our engineers carefully select the right PLC models based on the unique requirements of each application, optimizing performance and reliability.

Furthermore, we design and install PLC circuits to ensure protection against hazardous environments. This includes safeguarding systems from potential threats such as condensation, power surges, lightning, corrosive gases, and other environmental factors, guaranteeing the long-term stability and safety of your automation infrastructure.

We conduct detailed simulations and comprehensive debugging processes to minimize modifications during on-site testing and commissioning, resulting in more efficient and cost-effective project execution.

Fully tested and debugged before delivery

IIoT System Design and Integration

Data is securely stored in the cloud or on local servers, equipped with firewall and cybersecurity protections. Beyond storage, our system analyzes data for predictive and preventive maintenance, significantly reducing downtime and boosting productivity.

We offer customizable dashboard visuals—such as bar charts, line charts, and pie charts—to facilitate easy data comparison. Our solutions cater to a broad spectrum of operations, from small factories and farms to large industrial enterprises.

Partner with Thydaa Engineers to optimize your operations and enhance efficiency across your facility!

Custom Industry Software

At Thydaa Engineers, we provide fully customized software solutions, meticulously crafted to meet your factory’s specific needs. Each solution is exclusively developed for a single factory, ensuring perfect alignment with your unique processes and operational goals.

Our tailor-made approach includes features like automated performance calculations and customizable reporting formats, giving your team the essential tools to enhance efficiency and achieve success.

CEMS System Application and Calibration

• Installation and maintenance of Continuous Emission Monitoring Systems (CEMS) and CEMS Data Acquisition Systems (CEMS-DAS) at industrial premises.

• Installation and maintenance of CEMS Data Interfacing Systems (CEMS-DIS) for data transmission from CEMS-DAS to the DOE’s Remote Monitoring and Enforcement System.

•On-site calibration works to ensure the accuracy of the instruments.

PLC control systems used in industrial automation systems to control automation devices and processes.